The changchun optical payload manufacturing AIT focuses on the design, development, testing, and validation of large-aperture optical remote sensing satellite payloads. It also has a strong technical foundation in space remote sensing equipments, optoelectronic detection devices, and optoelectronic instruments. Changchun AIT independently develops complete optical remote sensing payloads and their core components, possessing capabilities and extensive experience in payload design, assembly, integration, and testing. It can provide comprehensive optoelectronic systems, instruments, and products for defense, industrial, and regional users.

The optical payload AIT center is a core facility dedicated to the comprehensive evaluation of optical system imaging quality. It uses methods like Rayleigh criterion, wavefront maps, spot diagrams, and MTF analysis to measure wavefront aberrations, energy distribution, resolution, and contrast transfer. This ensures satellite optical payloads function reliably in space by analyzing optical system aberrations, diffraction effects, and imaging performance.

The collimator is a precision optical instrument that generates parallel light beams to simulate distant targets, used for testing and calibrating high-precision optical equipment. It verifies stray light suppression, thermal-optical stability, and quickly validates imaging performance for optical payloads. The system supports optical testing and MTF (modulation transfer function) measurements.

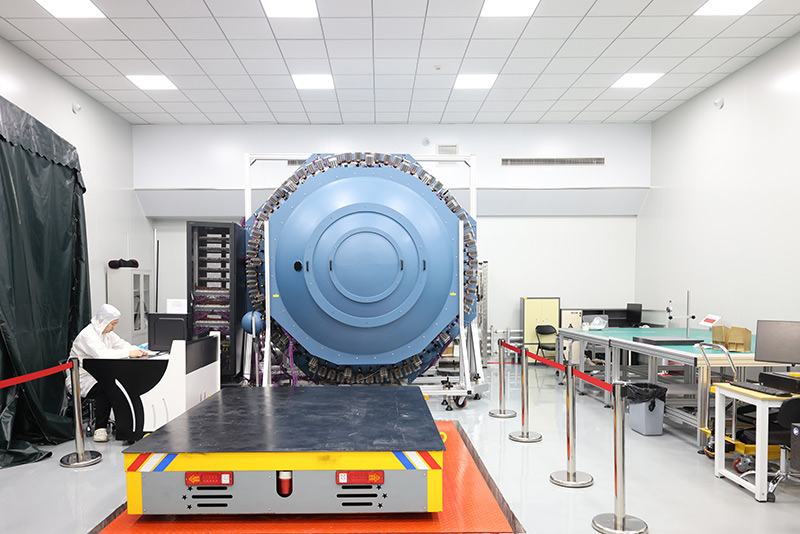

The integrating sphere is a powerful tool for optical measurements, featuring a 3-meter diameter with its inner wall coated with high-reflectivity diffuse reflection material to form an ideal spherical surface that ensures thorough and uniform diffuse reflection of light. It is capable of measuring parameters such as spectral characteristics and luminous flux of large lighting fixtures, while performing tasks including reflectance and transmittance testing, as well as spectral data collection.

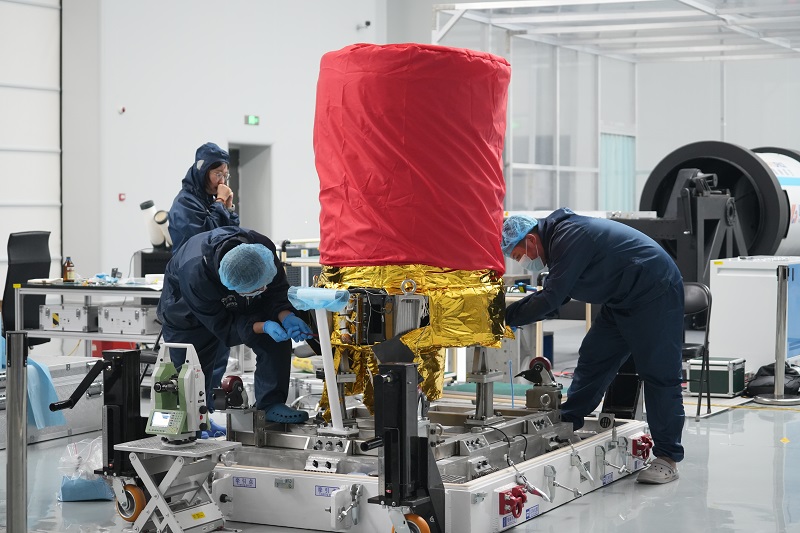

The assembly and alignment center is a core area integrating high-precision and cutting-edge technologies. It is equipped with advanced optical measurement instruments, precision assembly equipment, and intelligent debugging systems. A professional team assembles components such as optical lenses in accordance with technical specifications, conducts precise debugging and optimization of system performance, and resolves issues such as image quality degradation.

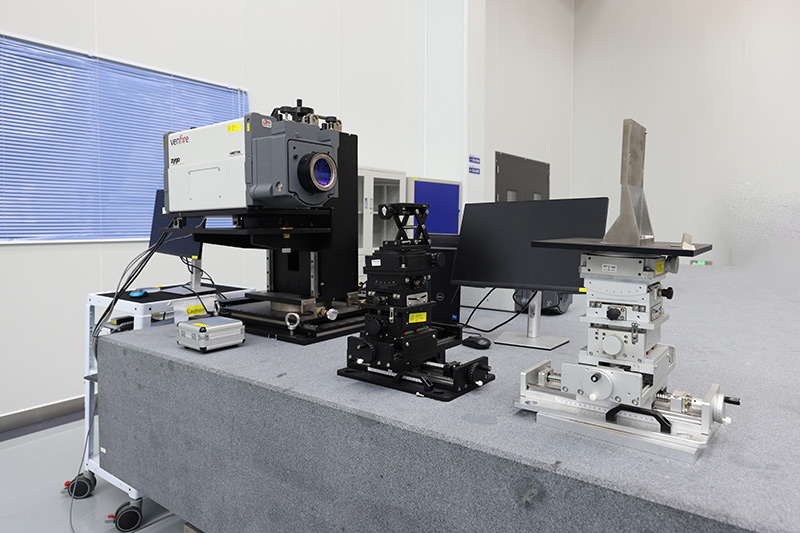

The laser interferometer is a core instrument for optical system testing. Using high-precision interferometry, it non-contact measures surface figure errors and wavefront aberrations to support component refinement. During final assembly, it measures transmitted wavefront distortion to verify system performance. Its adaptability to multiple models improves both efficiency and flexibility in optical testing workflows.

The detector assembly and inspection center ensures optical payload performance. With high-precision equipment, it achieves micron-level detector chip alignment and comprehensive optical verification. The team efficiently integrates multi-chip modules, identifies and eliminates defects through multi-dimensional testing, providing quality assurance for reliable space operation.

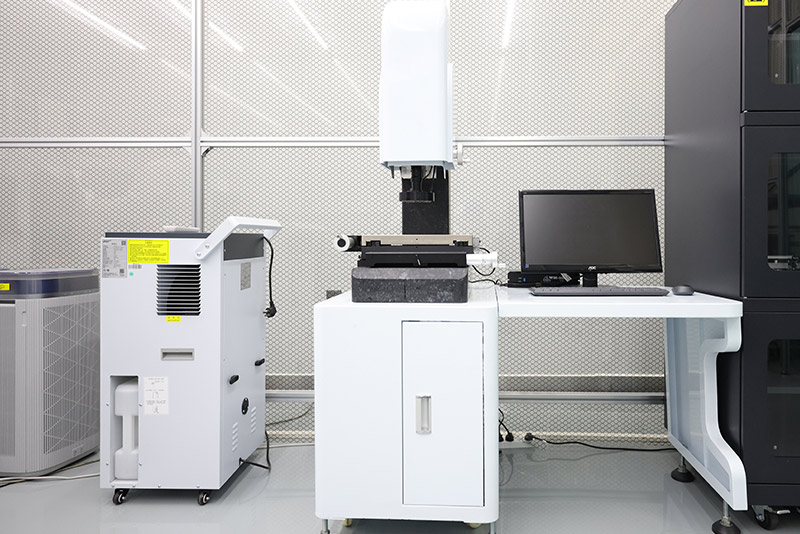

The three-axis toolmaker's microscope provides clear, upright images with a wide field of view. Its high-precision measurement meets JS B7153 standards. Using FS optical series objectives with long working distance and high NA, it combines metallurgical and measurement functions for high-resolution observation and precise measurement. With reflected/transmitted illumination and adjustable features, it ensures accurate inspection and analysis of various components.